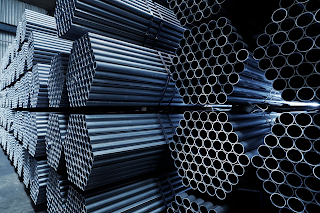

Characteristics of Seamless Tube

Seamless tube is a long strip of steel with a hollow section and no seams around it. Currently, there are more than 110 countries produce seamless tubes in the world. Xiangjia is a steel pipe manufacturer in the thousands of producer. Here we'd like to talk about the characteristics of seamless tube: First, the thicker the wall thickness of the product, the more economical and practical it is. However, the thinner wall process makes the cost higher; Secondly, the process of this product determines its limited performance. Generally, seamless steel pipes have low precision: uneven wall thickness, low brightness, high cost of fixed-length, and pits and black spots. Third, the detection and shaping must be processed offline. Therefore, its superiority refect on high pressure, high strength, and mechanical structural materials.

.jpg)